Foaming Machines

High and low pressure

Our foaming machines are designed down to the smallest detail to ensure they are extremely powerful, ultra-compact, easy to move around and, more importantly, easy to use.

Watch the video

ADVANTAGES

Preventive maintenance

Prevention is a key aspect of the machine.

Our foaming machines work remotely with our technical team, alerting them about possible threats in your machinery.

Technicians identify where they need to intervene and do so remotely or through augmented reality or on site.

Preventive maintenance is essential to ensure you work safely.

Customisation and automation

Our strong suit is designing ‘turnkey’ solutions on your foaming system.

We guide you through every stage of the process to create the right system for you.

A unique design in every respect

A unique design that conveys ease of use, reflecting the attention to detail and dedication we put into our work.

PED certification

Safety is important. Our safety components, such as valves, tanks and hydraulic accumulators, are PED-certified in accordance with regulation 2014/68/EU.

Mixing head

The head is fitted with an innovative and patented forced lubrication system to ensure the product flows smoothly and to avoid production halts.

Maintenance

Every component is within easy access for operators to perform routine maintenance on the system simply and quickly.

Tank thermostatic control

The isocyanate and polyol tanks maintain the ideal product temperature to fluidify it and make it flow through the pipes up to the mixing head.

Mixing head

The core of the system

It is built with the renowned ‘L chamber’ system to repeat the foaming process and provide a quality result.

It can be fitted either vertically or horizontally and the injection can be performed in either open or closed moulds.

The mixing head has two cylindrical chambers: the mixing chamber, inside which two injectors spray the two components at high speed and mix them, and a flow chamber through which the polyurethane during the reaction is discharged into the mould.

Tank

80 Kg

250 Kg

Control panel

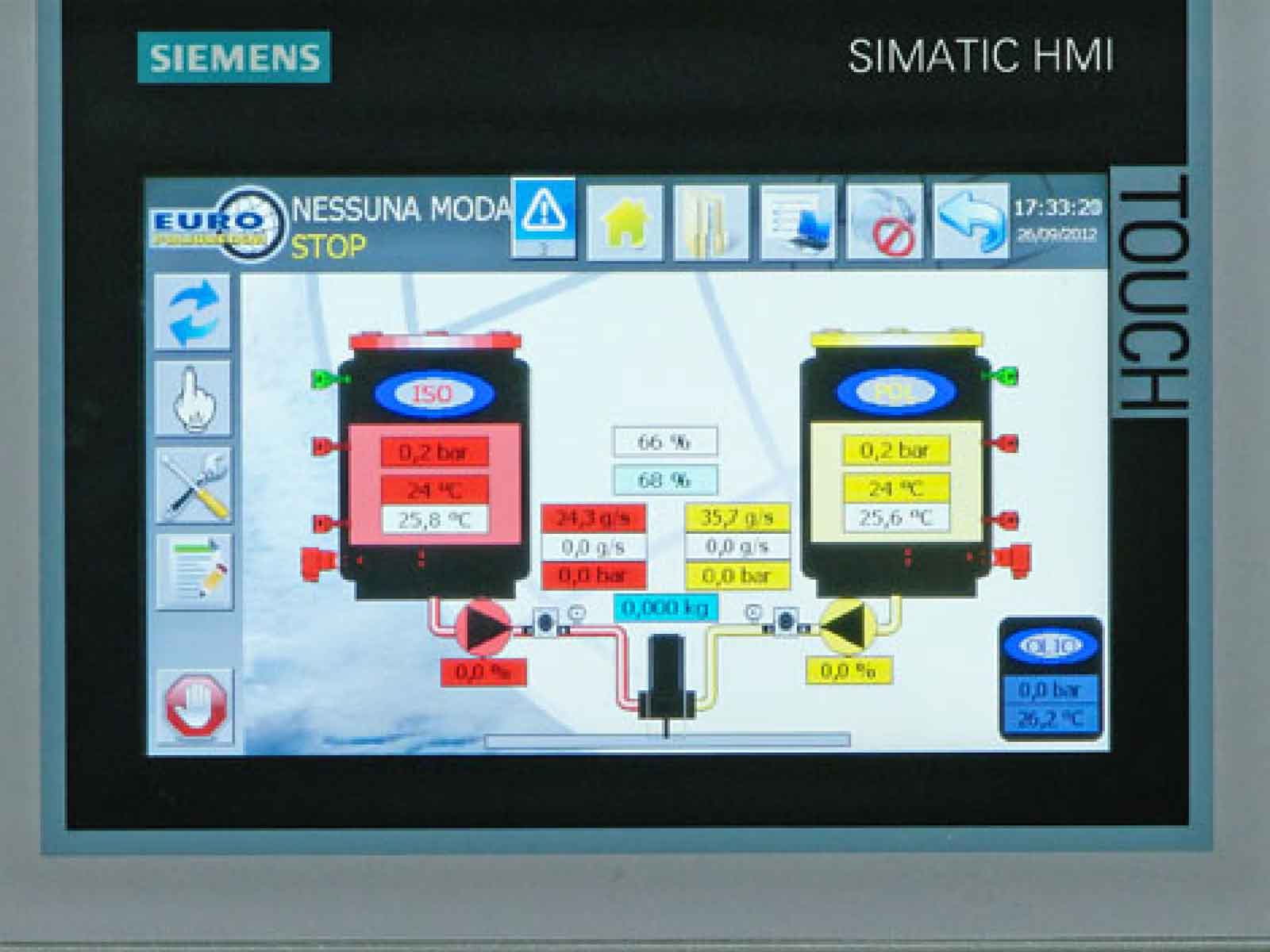

The PLC control panel with a 4” touch-screen interface features user-friendly graphics and is located on the mixing head to make it easier for operators to set operating parameters, including:

– the temperature and pressure of components

– Component ratio

– Amount of product dispensed in kg

– program number with 100 standard memory cells

– Flow rate setting in kg/min

OPTIONAL FEATURES

SCAMBIATORI DI CALORE

Per raggiungere una maggiore capacità di raffreddamento del prodotto chimico.

SENSORI DI LIVELLO

Per comandare l’apertura e la chiusura delle valvole di carico.

FLOW METER

Per avere costante monitoraggio della quantità erogata di isocianato e poliolo.

MIXER SERBATOI

Per Mantenere un’ottima miscelazione e termostatazione dei componenti.

STAMPANTE

Per la stampa su etichetta di : peso, peso reale iniettato, Rapporto d’impiego, Data, Nome cliente e prezzo.

100 PROGRAMMI

Per velocizzare il lavoro salvando il rapporto- pesi dei componenti.

BARCODE READER

Per leggere automaticamente quantità da iniettare all’interno del manufatto tramite codice a barre.

GRUPPO FRIGORIFERO

Refrigeratore per raffreddare l’acqua e mantenere il prodotto chimico termostato.

POMPE DI CARICO

Per caricare e mantenere il livello corretto del prodotto all’interno dei serbatoi.

ROUTER ASEM

Per collegare la macchina da remoto per prevenzione e controllo.

TOUCH SCREEN

Per impostare agevolmente i parametri e monitorare il lavoro.

Why customise your system?

We design and manufacture the best automated system for you to make your production more efficient.